Using the Current Sensing Relay for Diagnostics

This device can be extremely handy if you want to take monitoring to the next level. We have all had an instance where a pump was meant to start, the contactor energised, but the motor did not run. So how could we monitor this and trigger an alarm when it happens?

On your installation you have a high level float switch to start the pump, a low level to stop the pump and finally the high-high to trigger the alarm. The only problem is that when the high-high triggers, you need to scramble to try and fix it before you have water everywhere. Now let’s “buy” some time and set up a ‘failed to start’ alarm.

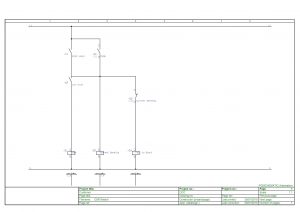

By installing a current sensing relay, we can determine whether the motor is actually drawing current when it has received a start signal. That means you can set up your circuit to alarm when it has a start signal but fails to draw current. Below is a sketch of what this could look like:

Please note: This circuit is indicative only. Check your requirements, control circuit etc. and wire to that.

There are many different brands available when it comes to these relays. Check what you want in terms of current levels and select one that can handle the current you are drawing on your motor. This one for instance measures from 2A to 20A, is easy to set up and does not cost too much:

Crouzet Current Monitoring Relay with SP-NO/NC Contacts, 24 → 240 V ac/dc (can be sourced from RS Components)

There we go. Another application for the current sensing relay that can save you time.

Have a look at these devices and see how you can introduce them to monitor machines, heating elements etc.

As usual, stay safe and test before you touch!