Where you need to ensure you have a standby unit ready to run in an emergency, it is important to be informed quick. In other words, there needs to be an alarm in place to notify you immediately the duty system fails. The last thing you want is for the failure to create additional issues before you get notified.

How can this be done?

Let’s take a pump installation. You have the primary or duty pump in service. What you need to do next is to look at what activates the system. Where you have a pressure switch triggering the pump to start, it is relatively easy to add an alarm. If the pressure switch ‘calls’ for the pump, you have two things that need to operate. First you need to activate/energise the contactor and next the pump needs to run.

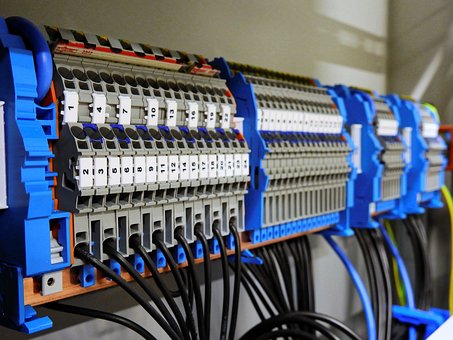

Start with your contactor. If it is meant to be energised, you can use an auxiliary contact to ‘tell’ you it has been energised. Where the pressure switch is on and the contactor remains de-energised, you can use this signal to trigger your alarm. Where the contactor has energised, the pump needs to run. This means it will draw current. By adding a current sensing device, you can trigger your alarm where no current is drawn when it should be running.

Is this ‘foolproof’?

Not yet. You also must look at the water side of the installation. You could have a mechanical failure where the pump is running, but no water is being delivered. Here you need to look at flow, and if it pumps to a storage vessel, you can add a level switch. By covering all your bases, you have the advantage of being notified the minute a problem occurs. This gives you time to get it sorted by switching to your standby unit quickly.

Depending on how it has been set up, you can automate the whole system by shutting down the faulty unit and automatically start the standby unit. Keep in mind you still want the alarm otherwise you will not know this has happened.

Wrapping Up

When you are doing an installation of this nature, look at every component that could fail and then design your system to ‘react’ to these failures. Always ask yourself “what if” when you do your design. You may also want to weigh up the cost for different applications. In other words, if the alarm system will cost $500 to install, but the consequence of system failure is $50, you may need to think twice before installing it unless the failures are frequent. Talk to your client and let him/her decide on what risks they are willing to absorb in the case of a failure.

Finally, stay safe out there and remember to isolate and lock out equipment you are working on.